Maximum performance thanks to 5-axis configuration

For maximum performance, LiFLEX twin spindle machines are mainly used in a 5-axis configuration.

High precision thanks to i³ technology

With LiCON i³ technology, both motor spindles on LiFLEX twin spindle machines can be corrected independently in all three main axes - X, Y and Z - without reducing spindle stiffness.

As productive as two single-spindle machines with reduced footprint

Digitally optimized machine structures ensure that both motor spindles can call up their full cutting performance on the workpiece without influencing each other. This makes LiFLEX twin spindle machines as productive as two single spindle machines, but they require significantly less space in the production hall.

Wide range of configuration options

The modular LiFLEX design principle allows you to configure LiFLEX twin spindle machines to meet your specific needs. You can choose from various loading options as well as different variants of motor spindles, tool magazines, tool changing systems and systems for process cooling.

LiFLEX II Twin-Spindle Machines

LiFLEX II twin spindle machines come with spindle distances from 400 mm to 1500 mm. Equipped with LiCON i³-technology, both motor spindles on LiFLEX twin-spindle machines can be corrected independently without reducing spindle stiffnesses.

LiFLEX II 444

Strokes of 450 / 500 / 420 mm in X / Y / Z

LiFLEX II 655

Strokes of 600 / 500 / 500 mm in X / Y / Z

LiFLEX II 766

Strokes of 750/ 660 / 650 mm in X / Y / Z

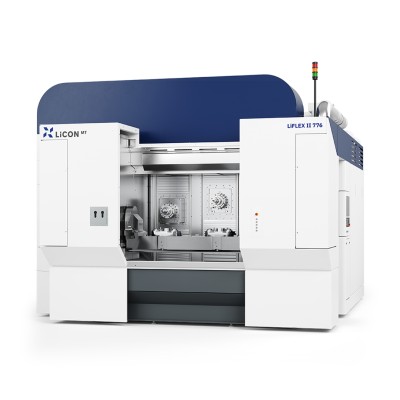

LiFLEX II 776

Strokes of 750 / 700 / 650 mm in X / Y / Z

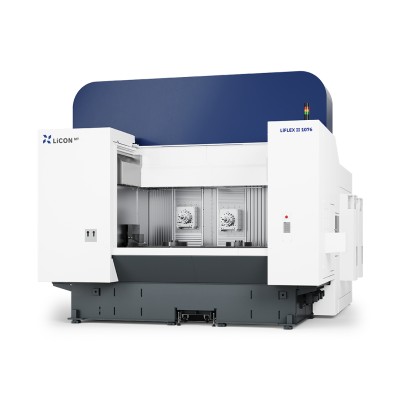

LiFLEX II 1076

Strokes of 1050 / 700 / 650 mm in X / Y / Z

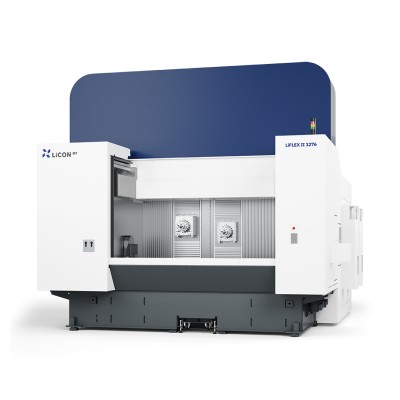

LiFLEX II 1276

Strokes of 1200 / 700 / 650 mm in X / Y / Z

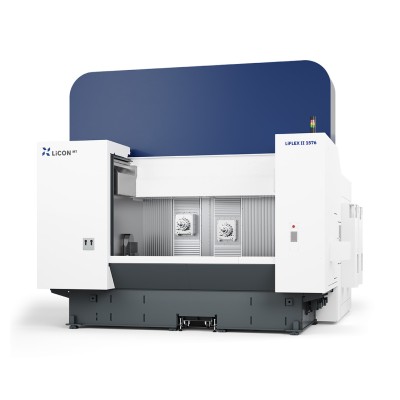

LiFLEX II 1576

Strokes of 1500 / 700 / 650 mm in X / Y / Z

Discover the Other Series of the LiFLEX Family.

In addition to LiFLEX II twin-spindle machines, the LiFLEX family also offers high-performance single-spindle and four-spindle machines. The LiFLEX GigaLine includes single- and twin-spindle machines for machining large and complex workpieces. Learn more about our LiFLEX series.