Maximum performance thanks to 5-axis configuration

For maximum performance, LiFLEX single-spindle machines are mainly used in a 5-axis configuration.

Machining of large components in only one clamping

For machining in only one clamping, it must be possible to position even large components almost arbitrarily in the working area. LiFLEX single-spindle machines offer correspondingly large diameters for swivelling the clamping devices in both rotational axes A and B.

Dynamic stiffness and remarkable dynamic values

LiFLEX I single-spindle machines have proven dynamic stiffness with remarkable dynamic values.

Wide range of configuration options

The modular LiFLEX design principle allows you to configure LiFLEX I single-spindle machines to meet your specific needs. You can choose from various loading options as well as different variants of motor spindles, tool magazines, tool changing systems and systems for process cooling.

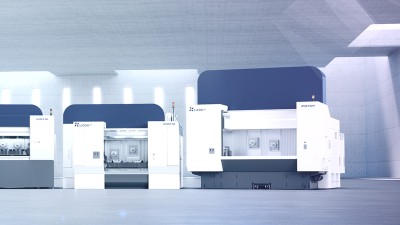

LiFLEX I Single-Spindle Machines

To avoid reclamping errors, large scale cubic workpieces mainly made of aluminum, are also completely processed in one clamping. For this reason, the workpiece must be able to be positioned appropriately in the working area. The LiFLEX I single-spindle machines offer correspondingly large diameters for the rotation of the clamping fixtures in the A and B axes.

LiFLEX I 755

Strokes of 750 / 550 / 500 mm in X / Y / Z

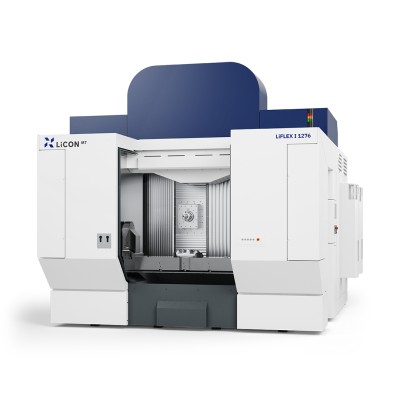

LiFLEX I 1276

Strokes 1250 / 700 / 650 mm in X / Y / Z

LiFLEX I 12126

Strokes of 1250 / 1250 / 650 mm in X / Y / Z

LiFLEX I 12126 HD

Strokes of 1250 / 1250 / 650 mm in X / Y /Z

Discover the Other Series of the LiFLEX Family.

In addition to LiFLEX I single-spindle machines, the LiFLEX family also offers high-performance double-spindle and four-spindle machines. The LiFLEX GigaLine includes single- and twin-spindle machines for machining large and complex components. Learn more about our LiFLEX series.