Body-In-White

The trend in design of automobile chassis using lightweight structures is still ongoing. To reduce assembly work further, more and more large workpieces – mainly made of die casts – are being utilized. The machining of these complex structural workpieces takes place on large, usually 5-axis machining centers.

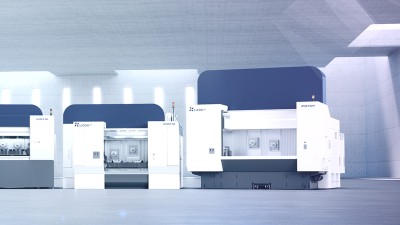

The existing LiFLEX modular system enables a tailormade configuration for such large giga machining centers both single-spindle and twin-spindle. In order to be able to machine large-cubic workpieces completely in one clamping, the workpiece must be able to be positioned appropriately in the working area. The LiFLEX GigaLine offers machines with a correspondingly large rotation diameter up to 2300 mm for fixtures in the two rotation axes A and B.

Highlights of our Giga

• Up to seven axes

• Workpiece sizes up to 3,000 mm

• Single and double spindle on a single workpiece

• Body-in-white-complete processing

LiFLEX I 4-axis

One large-dimensional machining task in one machine

• One spindle

• 4/5-axis machining

• Up to 3,000 mm X-stroke

LiFLEX I+I 5-axis

Two different machining tasks in one machine

• Two spindles

• 4/5-axis machining

• Spindle distance 600 – 2,500 mm

Discover the Other Series of the LiFLEX Family.

In addition to the LiFLEX GigaLine with large and dedicated machines, the LiFLEX family also includes single-spindle, twin-spindle and four-spindle machines with comparatively smaller strokes. Learn more about our LiFLEX series.