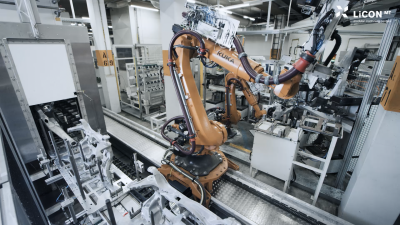

Automation Tailored to Requirements

We develop individual automation solutions matched to the specific needs of our customers. LiCON engineers focus not only on software development for controlling the automated plant network but also on the development and manufacture of the associated control system as well as all relevant mechanical components. Standard components, such as conveyor belts, and specific equipment, e.g., cleaning systems and deburring cells, are sourced from partner companies and integrated into the overall network in terms of control technology.

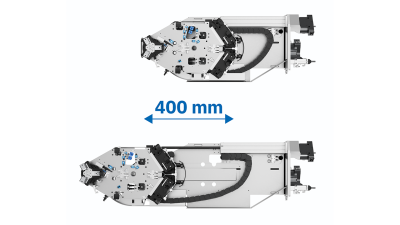

LiCON Workpiece Gripper

A key element of our LiCON automation solutions are LiCON workpiece grippers. Installed in front of the machine tool, the grippers enable loading and unloading of the workspace without personnel. In addition, they can allow an automated transport of workpieces via a seventh axis.

Gripping up to three different workpieces – e.g., alternately left and right semi trailing arm in combination with a subframe – makes LiCON workpiece grippers highly efficient. For maximum process reliability, we develop grippers and fixtures in-house so that they match perfectly.

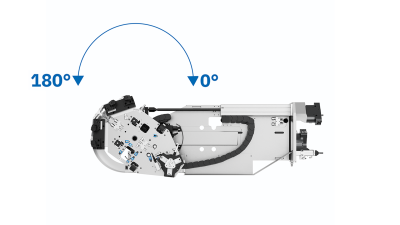

Linear and Rotary Function in One

LiCON workpiece grippers have both a linear extension and retraction function and a rotary function. In combination with a robot, LiCON workpiece grippers are the solution for process-reliable automation of production lines.

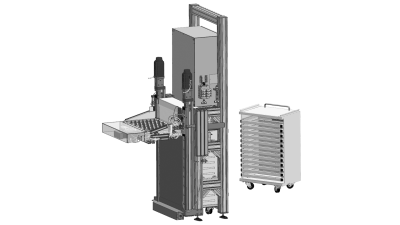

LiCON Stacking Cell

The LiCON stacking cell allows the stocking of a higher number of raw parts and the buffering of finished parts directly at the line. In combination with the LiCON workpiece grippers, a production operation of several hours can be realized without personnel. Thanks to the sophisticated design, the stacking cell can be flexibly adapted for different workpieces and offers a high storage capacity while requiring only small floor space.